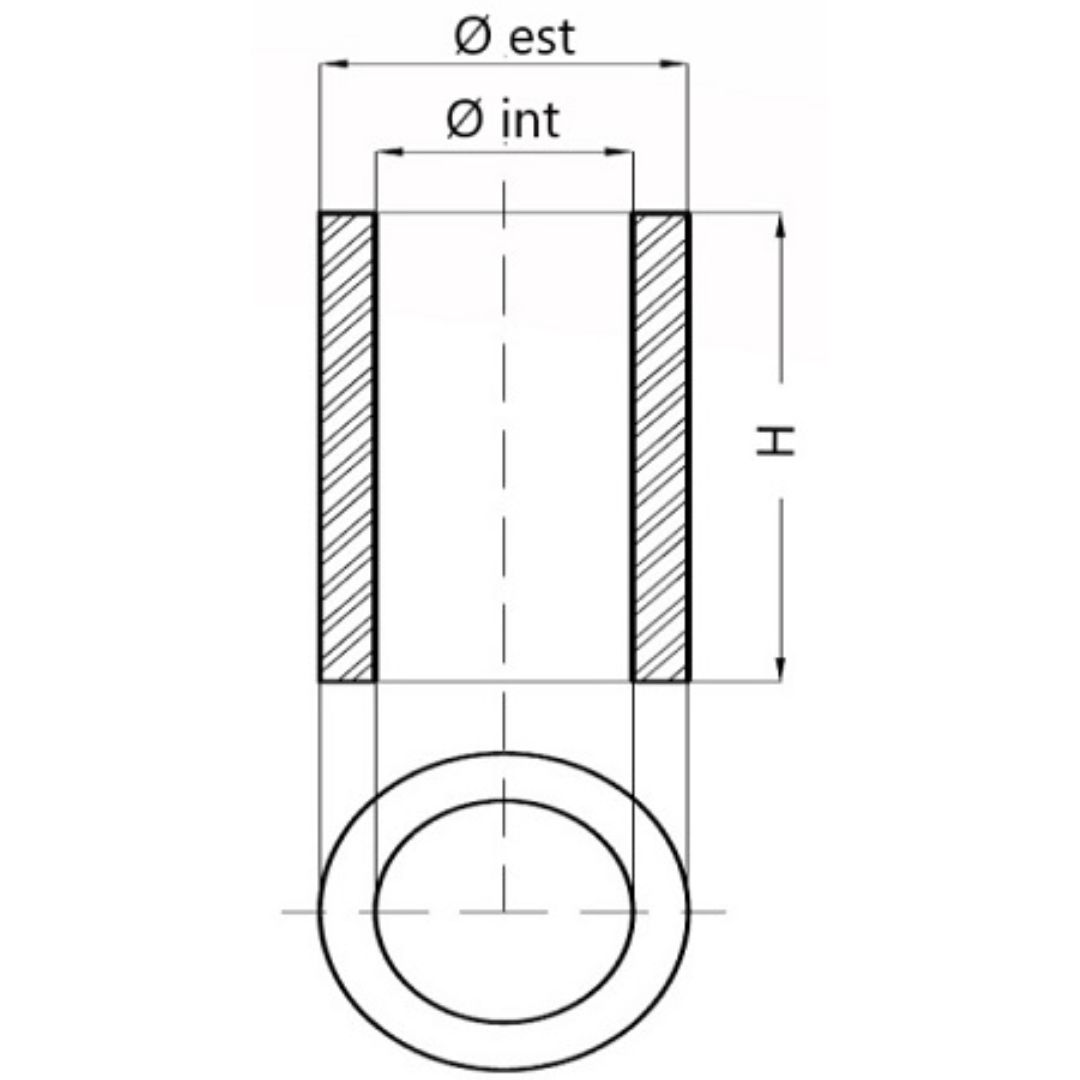

Cylindric filters in stainless steel wire

Inox 304 and INOX 316 stainless steel mesh/blanket filters from Sinterfilters are known for their excellent corrosion and high temperature resistance properties. These stainless steel alloys are commonly used in industrial environments and applications requiring durability and resistance to environmental factors. They offer a reliable and customised solution for a wide range of industrial applications. Thanks to their unique characteristics, they are able to guarantee efficient filtration and a long service life.

Main Features Filter Bushings Canvas/Inox Sheet:

Porosity from 15 to 2,000 microns

Mesh Number: 1.5 to 26,000/sq cm

Wire Diameter: 0.04 to 2 mm.

Filtration from 10 to 150 microns for wire

Filtration from 300 to 2000 microns for expanded metal.

- Resistant to fresh and salt water, saline solutions, sulphates, nitric acid, phosphoric acid

- Resistance to thermal shocks

- Resistance to high temperatures (up to about 500°)

- Good mechanical resistance

Sinterfiltri produces filters based on customer-specific designs. Experience, knowledge of materials, and manufacturing technologies are combined to design filters to meet your specific needs. FIND OUT if the filter is already manufactured in the "CATALOGUE" range. If you don't find the size you need, write to info@sinterfiltri.com to have the filter best suited to your needs made.

BRIEF DESCRIPTION:

When we talk about "clearance" in the context of wire mesh filtration, we're referring to the size of the openings or holes in the mesh. This is a fundamental characteristic that determines the size of particles that can pass through the filter and those that are retained.

- Wide clearance: If the holes are large, larger particles will be able to pass through the filter. This is useful when coarse filtration or a high liquid/gas flow rate is desired.

- Narrow clearance: If the holes are small, only very fine particles will pass through the mesh, ensuring more precise filtration and the removal of smaller impurities.

"Clearance" is often expressed in different units of measurement, depending on standards and manufacturer specifications. Some of the most common include:

- Microns (µm): Indicates the actual size of the opening in micrometers (millionths of a meter).

- Mesh: Indicates the number of threads per linear inch (25.4 mm). A higher mesh number means smaller holes and therefore a smaller gap. The relationship between mesh and opening size is not linear and also depends on the diameter of the thread used to weave the canvas.

- Millimeters (mm): In some cases, especially for canvases with larger openings, the gap can be expressed directly in millimeters.

A wide aperture generally implies the use of thinner threads.

- Maximize the passage area: The goal of a wide aperture is to allow the passage of larger particles and/or ensure a high flow rate of the fluid or gas. To achieve large apertures, thinner threads must be used. Thicker threads would take up more space in the mesh, reducing the effective size of the holes.

- Space-to-thread ratio: Imagine a grid. If you want the "holes" (the aperture) to be large, you need to use thinner "bars" (the threads). If the bars were thicker, the holes would be smaller, even if the distance between the bars were the same.

This is not an absolute rule, and the final choice depends on a balance of different filtration application requirements, mechanical resistance, type of filtered material, and weaving process.

You can sort the list and perform a search by filling in the appropriate filter fields. NB: Unit of measurement: Thread expressed in mm - Light expressed in microns

Boccole Tela Inox

Description

Main features of Sinterfiltri filters:

AISI 304/316 Stainless Steel:

- Corrosion Resistance: Both AISI 304 and AISI 316 alloys offer excellent levels of corrosion resistance. AISI 316, thanks to the presence of molybdenum, offers greater resistance in more aggressive or chloride-containing environments.

- High Temperature Resistance: Both alloys have good resistance to high temperatures, making them suitable for applications in thermally demanding environments.

- Strength and Durability: AISI 304 and 316 stainless steels are known for their mechanical strength and durability, ensuring that filters maintain their performance even under intensive use.

- Machinability and Weldability: They are easily machinable and can be welded, allowing for greater flexibility in design and installation.

- Design Flexibility: Disc filters are available in a wide range of sizes, thicknesses, and shapes to suit specific filtration needs.

- Easy Maintenance: The disc structure simplifies filter maintenance and cleaning, helping to ensure consistent performance over time. time.

Sinterfiltri manufactures and sells AISI 304 and AISI 316 stainless steel wire mesh and sheet metal filters. These high-quality filtration devices are designed to ensure reliable performance and long life in a variety of industrial applications. Here are the main features of these filters:

They are made by intertwining metal wires that create a filtering surface made of fine meshes. This structure retains solid particles while allowing fluid or gas to pass through the filter surface. Thanks to this configuration, disc filters are effective for a wide range of industrial applications requiring the separation of particles from a fluid or gas. They are commonly used in industries such as the food, chemical, pharmaceutical, and many others. Their structure allows for easy cleaning and simple maintenance, ensuring consistent performance over time.

They are obtained through a cold sheet metal deformation process. This process allows for the creation of regular openings of various shapes, such as rhomboids, squares, and rounds, with specific dimensions. The expanded metal is subjected to a deformation process without heating, which means it maintains its structural properties while the holes are created. These filters are widely used in a wide range of industrial applications for the separation of solid particles from fluids or gases. Thanks to their precise structure and regular openings, they offer reliable and consistent filtering performance. They are particularly suitable for applications requiring the accurate separation of particles of different sizes.

Application Areas:

- Food and Beverage Industry: Sinterfiltri's stainless steel disc filters are ideal for the separation of solid particles from liquids or gases in food and beverage production processes.

- Chemical and Pharmaceutical Industry: They find application in environments that require maximum purity and efficient separation of particles from fluids and gases.

- Petrochemical and Energy Industry: They are used in production and treatment processes of fluids such as oils and fuels, helping to avoid contamination.

- Water and Waste Water Industry: They are used to remove sediments and impurities from water in treatment and purification plants.

- Aerospace and Defence Industry: They find use in applications requiring reliable filtration in critical environments such as those in the aerospace and defence industry.

- Electronics and Semiconductor Manufacturing: They are used to maintain extremely clean production environments, which are essential for the manufacture of electronic components.

- Automotive: They find application in lubrication systems and cooling circuits, where ensuring cleanliness of fluids is essential.

Sinterfiltri's Metal Canvas and Expanded Metal Sheet bushing filters offer a reliable, customised solution for a wide range of industrial applications.

Due to their unique characteristics, they provide efficient filtration and a long service life.

Request info

Custom filters

If you don't find the filter with the dimensions, particle size, or features you need in the catalog, please contact us at

info@sinterfiltri.com

or fill out the information request form to request a feasibility study and quote.