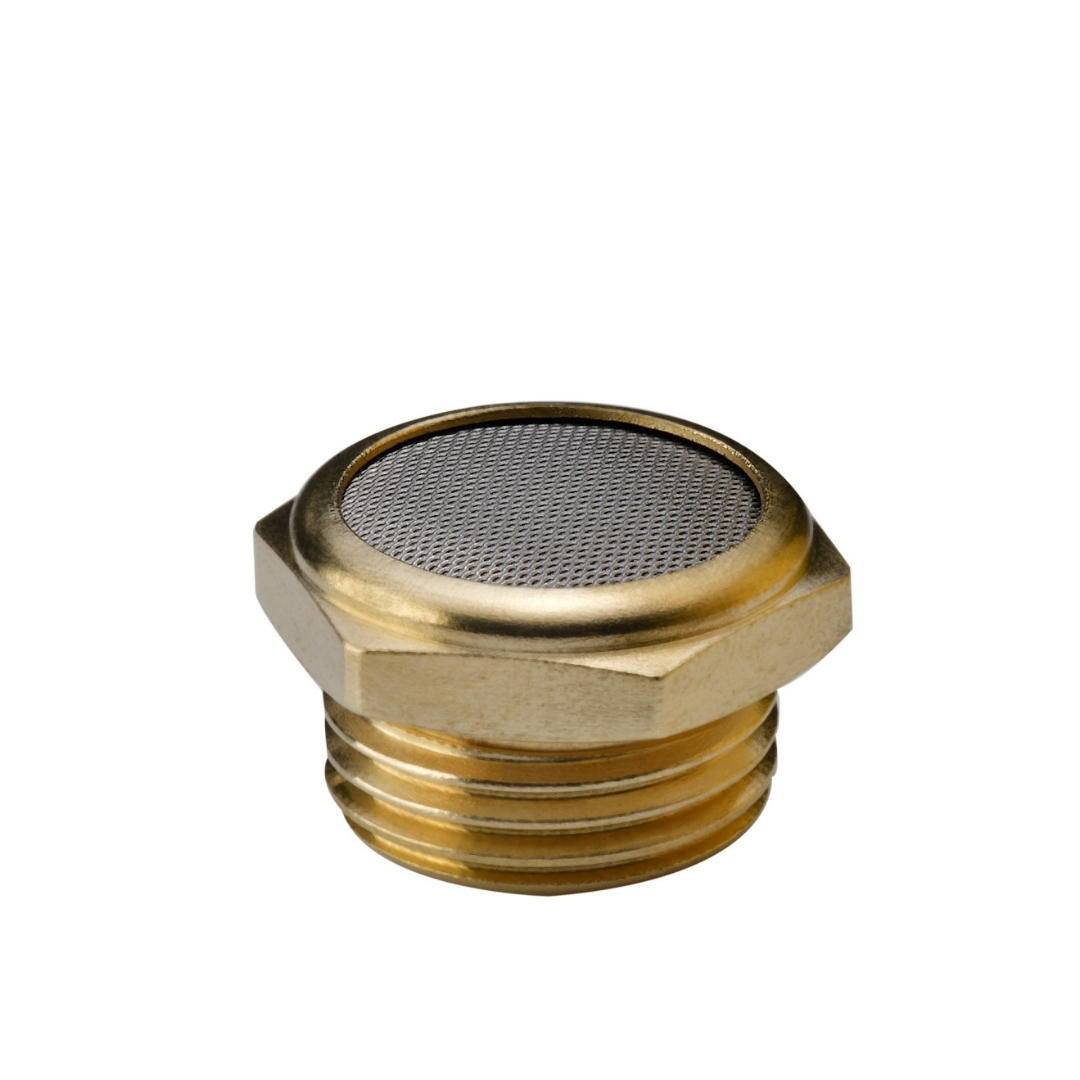

SERM stainless steel mesh silencer

The SERM silencer with AISI 304 stainless steel micro-perforated mesh is manufactured by Sinterfiltri with the following characteristics:

Filtering component composition: Stainless steel mesh

Filtration threshold: from 5µ to 120µ

Manufacturing tolerances: +/- 3%

Base: Hexagonal

Connection: brass

Thread: GAS-BSP ref. UNI EN ISO 228-1:2003

Sinterfiltri's SERM silencers with micro-perforated mesh in AISI 304 stainless steel are high-quality products used for a wide range of applications.

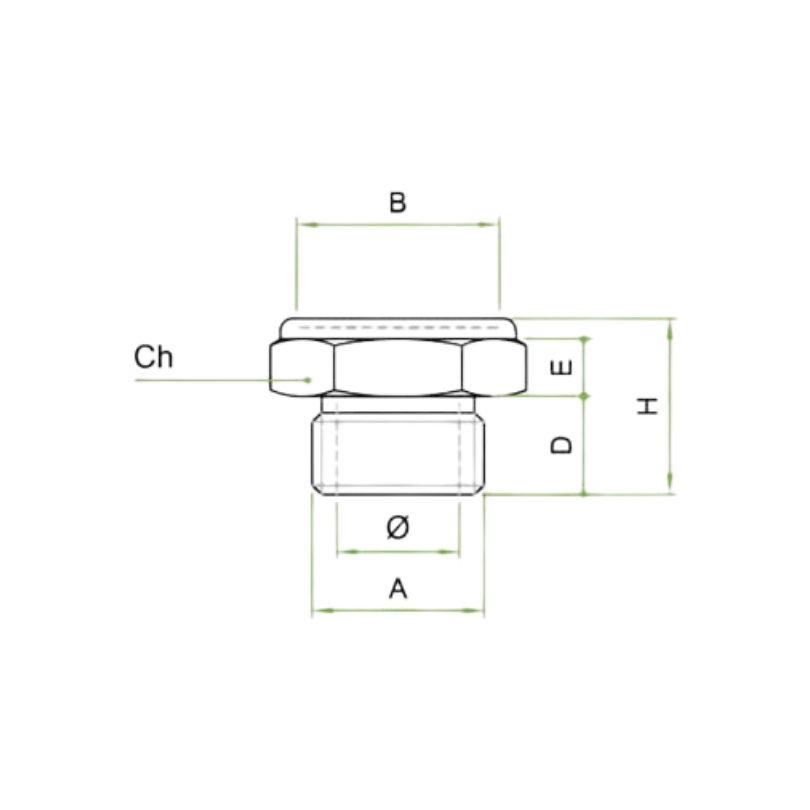

Units of measurement expressed in millimeters - tolerances ref. EN-22768 ISO-2768-c standard. Measurement ch +0/-0.10 mm

Silenziatore SERM con rete microforata in acciaio inox AISI 304

Description

Sinterfiltri's SERM filters, silencers with micro-perforated mesh in AISI 304 stainless steel riveted to a hexagonal brass base, are high-quality products used for a wide range of industrial applications. Their porous structure allows for the filtration of fluids and gases, while the silencer design reduces noise and vibrations produced by the flow of liquid or gas. The micro-perforated mesh used in the filters offers a surface with very small holes. This allows for the effective filtration of small particles, ensuring greater precision in the separation of impurities. Thanks to their filtering and silencing properties, these products are used in many sectors, such as the automotive, aerospace, and food industries. Furthermore, sintered bronze filter silencers are highly customizable and can be custom-designed to meet specific application needs.

SERM Silencers, with AISI 304 stainless steel micro-perforated mesh, are manufactured in Italy by Sinterfiltri and designed for:

- Industrial automation applications, on systems and machinery using compressed air

- Vacuum applications

- Special applications

- Air exhaust applications, valves, and pneumatic cylinders

- Other applications upon request

Request info

Custom filters

If you don't find the filter with the dimensions, particle size, or features you need in the catalog, please contact us at

info@sinterfiltri.com

or fill out the information request form to request a feasibility study and quote.