Filters

Production of Sintered Filters and Silencers, catalogue sales and production to customer's design request

Sintered Bronze Dust Filters

The resistance to oxidation of sintered bronze allows these filters to be used in a wide range of applications, particularly suitable in the hydraulic and pneumatic sectors. The slight variations to temperature changes, the high permeability coefficient, the ease of cleaning, and the good mechanical resistance are the main characteristics that have determined the considerable development in the use of this material.

Description

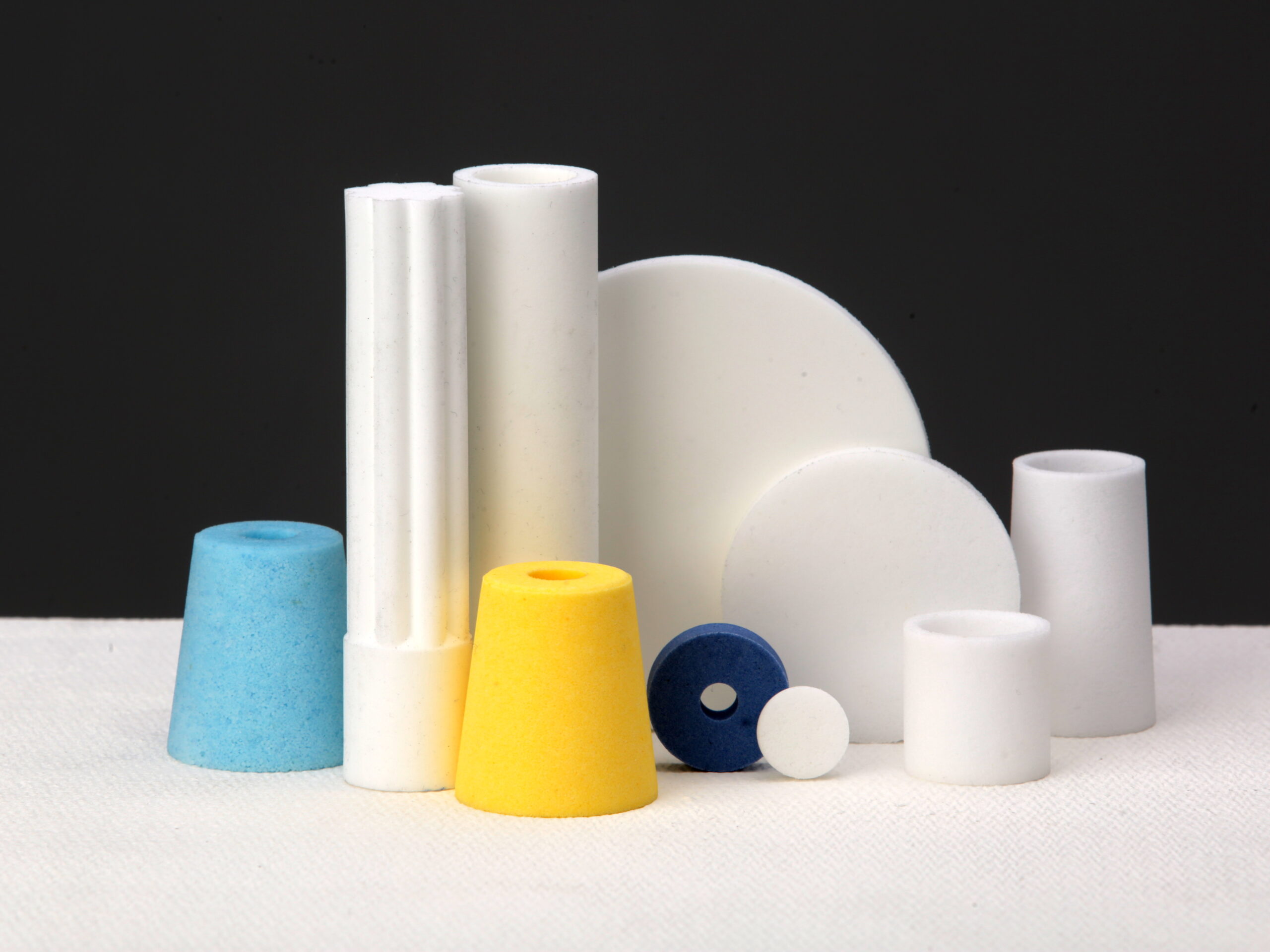

There are so many shapes, sizes and grain sizes that can be used. Therefore, although we have a well-stocked mould warehouse, we reserve the right to examine specific customer requirements.

We propose the best technical solution on a case-by-case basis and carry out the necessary tooling where necessary.

Sintered bronze filters from Sinterfiltri are a highly effective solution for the filtration of liquids and gases. These filters consist of a mixture of bronze powders that is compressed and sintered at high temperature to create a labyrinth-like porous structure. This porous structure creates a labyrinth of passages that trap particles and prevent them from passing through the filter.

Sintered bronze filters are highly resistant to corrosion and pressure, and can be used in a wide range of industrial applications, such as the chemical, oil, food, pharmaceutical and many other industries. Sintered bronze filters are available in different shapes and sizes to meet the specific needs of each application. The most common shapes of sintered bronze filter are disc, cylinder, plate, washer and cone. These can be installed in a variety of filtration devices, such as cartridge filters, pressure filters and gravity filters.

Sintered bronze filters have several advantages over other types of filters. Firstly, they have a higher particle retention capacity than traditional paper or fabric filters. Furthermore, they can be easily cleaned and reused many times without loss of efficiency. Furthermore, they are resistant to corrosion and high temperatures, making them ideal for use in industrial applications.

In conclusion, sintered bronze filters are an excellent choice for liquid and gas filtration in a wide range of applications. Their high filtration efficiency, corrosion resistance and ease of cleaning and reuse make them an economical and convenient choice for companies looking for a reliable, high quality filtration solution.

Our products are:

Sintered bronze filters

Open-pore bronze filters

Controlled porosity bronze filters

Porous bronze filter elements

Porous bronze filters

Industrial sintered bronze filters

Sintered bronze fluid filters

Sintered bronze gas filters

Sintered bronze liquid filters

Customised bronze filters

Precision bronze filters

Sintered bronze process filters

Filters for the chemical industry in bronze

Filters for the oil industry in sintered bronze

Filters for the food industry in bronze

We propose the best technical solution on a case-by-case basis and carry out the necessary tooling where necessary.

Sintered bronze filters from Sinterfiltri are a highly effective solution for the filtration of liquids and gases. These filters consist of a mixture of bronze powders that is compressed and sintered at high temperature to create a labyrinth-like porous structure. This porous structure creates a labyrinth of passages that trap particles and prevent them from passing through the filter.

Sintered bronze filters are highly resistant to corrosion and pressure, and can be used in a wide range of industrial applications, such as the chemical, oil, food, pharmaceutical and many other industries. Sintered bronze filters are available in different shapes and sizes to meet the specific needs of each application. The most common shapes of sintered bronze filter are disc, cylinder, plate, washer and cone. These can be installed in a variety of filtration devices, such as cartridge filters, pressure filters and gravity filters.

Sintered bronze filters have several advantages over other types of filters. Firstly, they have a higher particle retention capacity than traditional paper or fabric filters. Furthermore, they can be easily cleaned and reused many times without loss of efficiency. Furthermore, they are resistant to corrosion and high temperatures, making them ideal for use in industrial applications.

In conclusion, sintered bronze filters are an excellent choice for liquid and gas filtration in a wide range of applications. Their high filtration efficiency, corrosion resistance and ease of cleaning and reuse make them an economical and convenient choice for companies looking for a reliable, high quality filtration solution.

Our products are:

Sintered bronze filters

Open-pore bronze filters

Controlled porosity bronze filters

Porous bronze filter elements

Porous bronze filters

Industrial sintered bronze filters

Sintered bronze fluid filters

Sintered bronze gas filters

Sintered bronze liquid filters

Customised bronze filters

Precision bronze filters

Sintered bronze process filters

Filters for the chemical industry in bronze

Filters for the oil industry in sintered bronze

Filters for the food industry in bronze

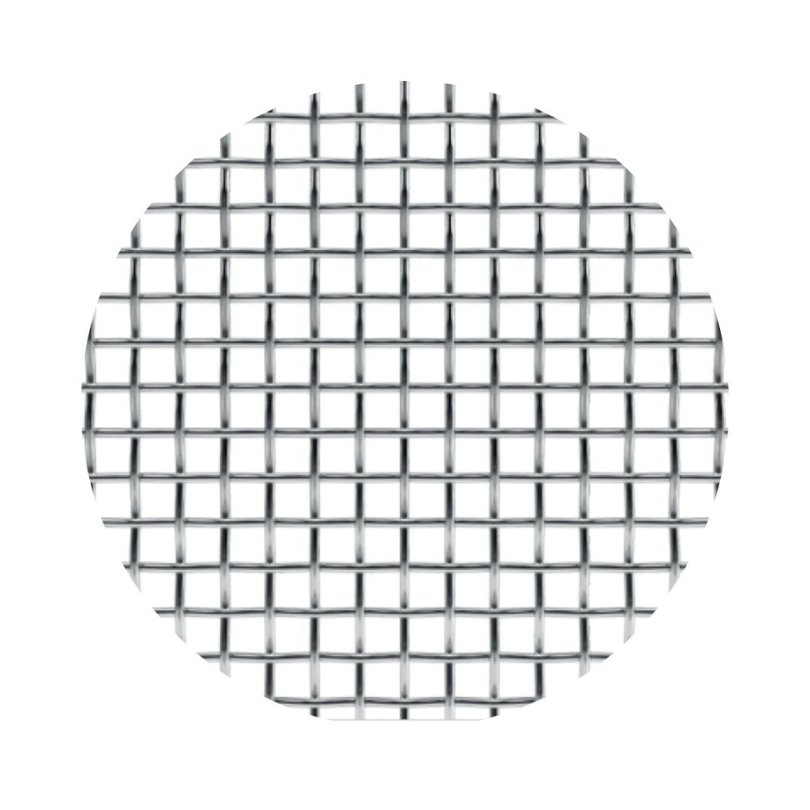

Wire and wire cloth filters stainless steel INOX AISI 304/316

Sinterfiltri manufactures and sells wire and wire cloth filters made of stainless steel Inox Aisi 304/316. Sinterfiltri products are reliable solutions for every industrial application!

Description

Sinterfilter products such as wire and wire cloth filters are designed and manufactured with high quality AISI 304/316 stainless steel materials and state-of-the-art production techniques, these filters are ideal for a wide range of industries.

Distinctive features:

Premium Materials: We use premium metal alloys such as AISI 304/316 stainless steel INOX to ensure strength, durability and optimum performance even under the most demanding conditions.

Advanced Metallic Fabric: The wire and wire cloth are manufactured from precisely braided or welded metal wires to create a robust and effective filter surface. This ensures accurate and consistent filtration.

Customised adaptability: We offer a wide range of sizes, shapes and configurations to meet the specific needs of each application. In particular, a wide range of Bushings and Discs, we have the perfect solution for you.

Maximum Corrosion Resistance: Sinterfilters are designed to withstand the most aggressive conditions, ensuring reliable performance even in corrosive environments.

Application opportunities:

Food and Beverage Industry: Raise the quality of your food and beverage products with filters that guarantee maximum purity and safety.

Chemical and Pharmaceutical Production: Maintain high quality standards and ensure the purity of your chemical and pharmaceutical products.

Automotive: Ensure that key vehicle components operate at peak performance with high-precision filter products.

Aerospace and Defence: Rely on Sinterfiltri products to ensure maximum cleanliness and reliability in critical aerospace and defence systems.

Cooling and Air Conditioning Systems: Protect your systems from damage and malfunction with filters that keep water clean and free of contaminants.

Electronics and Semiconductor Manufacturing: Avoid costly breakdowns and malfunctions with filters that ensure ultra-clean production environments.

Water and Waste Water Treatment: Contribute to a healthier, more sustainable environment with filters that purify waste water and industrial fluids.

Elevate the performance of your industrial process with wire cloth filter products. Contact us to find the perfect solution for your filtration needs!

Distinctive features:

Premium Materials: We use premium metal alloys such as AISI 304/316 stainless steel INOX to ensure strength, durability and optimum performance even under the most demanding conditions.

Advanced Metallic Fabric: The wire and wire cloth are manufactured from precisely braided or welded metal wires to create a robust and effective filter surface. This ensures accurate and consistent filtration.

Customised adaptability: We offer a wide range of sizes, shapes and configurations to meet the specific needs of each application. In particular, a wide range of Bushings and Discs, we have the perfect solution for you.

Maximum Corrosion Resistance: Sinterfilters are designed to withstand the most aggressive conditions, ensuring reliable performance even in corrosive environments.

Application opportunities:

Food and Beverage Industry: Raise the quality of your food and beverage products with filters that guarantee maximum purity and safety.

Chemical and Pharmaceutical Production: Maintain high quality standards and ensure the purity of your chemical and pharmaceutical products.

Automotive: Ensure that key vehicle components operate at peak performance with high-precision filter products.

Aerospace and Defence: Rely on Sinterfiltri products to ensure maximum cleanliness and reliability in critical aerospace and defence systems.

Cooling and Air Conditioning Systems: Protect your systems from damage and malfunction with filters that keep water clean and free of contaminants.

Electronics and Semiconductor Manufacturing: Avoid costly breakdowns and malfunctions with filters that ensure ultra-clean production environments.

Water and Waste Water Treatment: Contribute to a healthier, more sustainable environment with filters that purify waste water and industrial fluids.

Elevate the performance of your industrial process with wire cloth filter products. Contact us to find the perfect solution for your filtration needs!

Sintered porous plastic dust filters

Sinterfiltri, building on its more than ten years' experience in the production of sintered bronze filters, has recently poured its specific knowledge into activating the production of porous plastic material in line with new market requirements.

Description

The components obtained by sintering plastic manage to have efficient and excellent solid particle filtration combined with liquid and gas fluidity.

Constant particle size, bound by a precise cycle of operations and controlled temperature allow the production of components with different filtration, which lend themselves to a variety of applications such as filtration, gas diffusion and exhaust, and sound deadening. These products are hydrophobic and hydrophilic.

The porous plastic produced by Sinterfiltri retains its physical and mechanical properties even after the complicated production process characteristic of sintered material and guarantees high filtration efficiency and excellent soundproofing.

Constant particle size, bound by a precise cycle of operations and controlled temperature allow the production of components with different filtration, which lend themselves to a variety of applications such as filtration, gas diffusion and exhaust, and sound deadening. These products are hydrophobic and hydrophilic.

The porous plastic produced by Sinterfiltri retains its physical and mechanical properties even after the complicated production process characteristic of sintered material and guarantees high filtration efficiency and excellent soundproofing.

Main characteristics

Chemically resistant to most solvents, acids and hydrocarbons

Excellent corrosion resistance

High strength and light weight

Hydrophilic, hydrophobic properties

Max. temperature 90°C

Filtration 5 to 80 microns

Chemically resistant to most solvents, acids and hydrocarbons

Excellent corrosion resistance

High strength and light weight

Hydrophilic, hydrophobic properties

Max. temperature 90°C

Filtration 5 to 80 microns

Production possibilities

Prototype sampling

Small series

Large series

Production of parts to drawing

Prototype sampling

Small series

Large series

Production of parts to drawing

Sintered porous plastic filters manufactured by Sinterfiltri are an innovative solution for filtering gases and liquids in a wide range of industrial applications. These filters consist of a high-strength porous plastic material that is compressed and sintered at high temperature to create a fine pore structure. Sintered porous plastic offers several advantages over other types of filters. Firstly, its corrosion and high temperature resistant material makes it ideal for use in harsh industrial environments. In addition, its controlled porosity offers greater filtration efficiency than traditional paper or fabric filters.

Sintered porous plastic filters are highly customisable and available in a wide range of sizes and shapes. This allows you to choose the filter that best suits your specific filtration needs. Filters can be made in various shapes, including discs, tubes, sheets, plates and customised shapes.

Sintered porous plastic is also easy to clean and reuse many times without loss of efficiency. This means that sintered porous plastic filters are an economical and sustainable solution for long-term filtration. Sintered porous plastic filters find many applications in a wide range of industries, including the chemical, oil, food, pharmaceutical, automotive and many others.

In conclusion, sintered porous plastic filters represent an innovative and effective solution for gas and liquid filtration in many industrial applications. Their high filtration efficiency, resistance to corrosion and high temperatures, customised shapes and ease of cleaning and reuse make them an ideal choice for companies looking for a high-quality, sustainable and cost-effective filtration solution.

Sintered porous plastic filters are highly customisable and available in a wide range of sizes and shapes. This allows you to choose the filter that best suits your specific filtration needs. Filters can be made in various shapes, including discs, tubes, sheets, plates and customised shapes.

Sintered porous plastic is also easy to clean and reuse many times without loss of efficiency. This means that sintered porous plastic filters are an economical and sustainable solution for long-term filtration. Sintered porous plastic filters find many applications in a wide range of industries, including the chemical, oil, food, pharmaceutical, automotive and many others.

In conclusion, sintered porous plastic filters represent an innovative and effective solution for gas and liquid filtration in many industrial applications. Their high filtration efficiency, resistance to corrosion and high temperatures, customised shapes and ease of cleaning and reuse make them an ideal choice for companies looking for a high-quality, sustainable and cost-effective filtration solution.