SPPE Sintered Polythene Silencer

The SPPE Sintered Polythene Silencer in static plastic is manufactured by Sinterfiltri with the following characteristics:

Filter: Sintered HDPE Polythene

Fluid: Air

Filtration: 50

Operating Pressure: 10 bar

Operating Temperature: -20° C. +80° C

Tolerances: ISO 2768 C

Connection: Nylon 6

Thread: GAS-BSP ref. UNI EN ISO 228-1:2003

(*) Items with M codes have a metric thread

Sinterfiltri's SPPE sintered polythene silencers are high-quality products used for a wide range of applications.

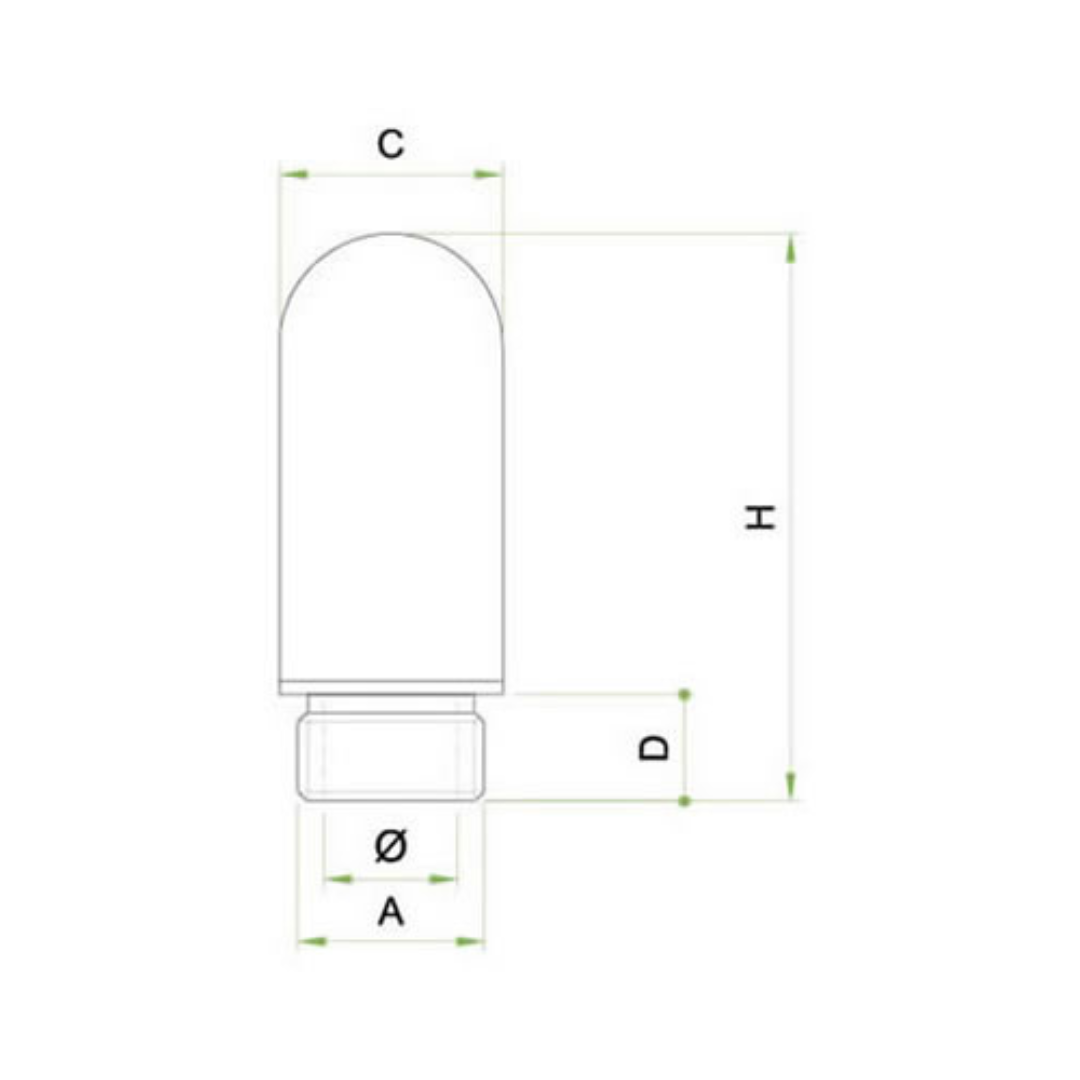

Units of measurement expressed in millimeters - tolerances ref. EN-22768 ISO-2768-c standard

Noise level

Noise level / noise level dB 5 BAR

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 |

| 83.6 | 86.8 | 88.3 | 91.7 | 97.5 | 105 |

Description

The sintered polythene SPPE silencer filter from Sinterfiltri is used to reduce noise and dampen vibrations in various applications, such as ventilation systems, exhaust systems, and industrial machinery. Sintered polythene is a porous material obtained through a polyethylene sintering process, which creates a structure with interconnected pores. The sintered polythene silencer filter exploits the sound-absorbing and filtration properties of the porous material to reduce noise generated by air or fluid flows. The pores in the sintered polythene act as air chambers that capture and disperse acoustic energy, thus reducing the noise level. This type of filter can be used in various sectors, such as the automotive industry, the chemical industry, the wind energy sector, and many others. It offers numerous advantages, including good chemical resistance, low pressure drop and long life.

SPPE Silencers, with sintered polythene cartridges, are manufactured in Italy by Sinterfiltri and designed for:

- Industrial automation applications, on systems and machinery using compressed air

- Vacuum applications

- Special applications

- Air exhaust applications, valves, and pneumatic cylinders

- Other applications upon request

Request info

Custom filters

If you don't find the filter with the dimensions, particle size, or characteristics you need in the catalog, please write to info@sinterfiltri.comor fill out the information request form to request feasibility and a quote.